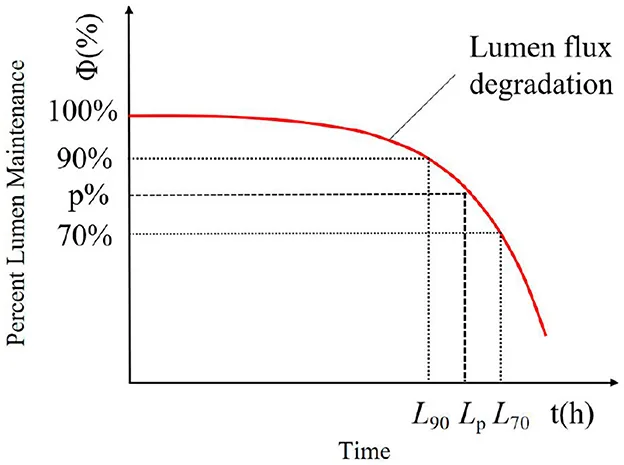

Deep Insights and Control Strategies on Lumen Degradation

I. The Nature of Lumen Degradation and the Industry Pain Point

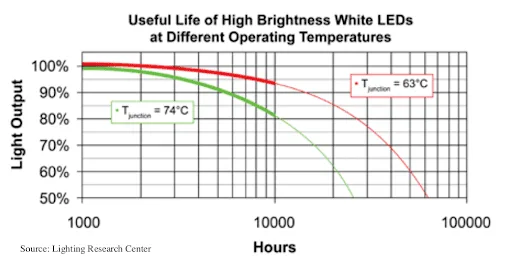

Example of lumen depreciation, over time, based on junction temperature. Source: Lighting Research Center

Because when brightness drops by more than 30%, the human eye can clearly perceive the dimming. Therefore, the industry generally defines the “L70 point” — when brightness falls to 70% — as the end of the LED’s useful life.Whether this lifespan meets the promised duration depends on the synergy between thermal management, current control, and material reliability.Core Factor: Chip Junction Temperature (Tj)

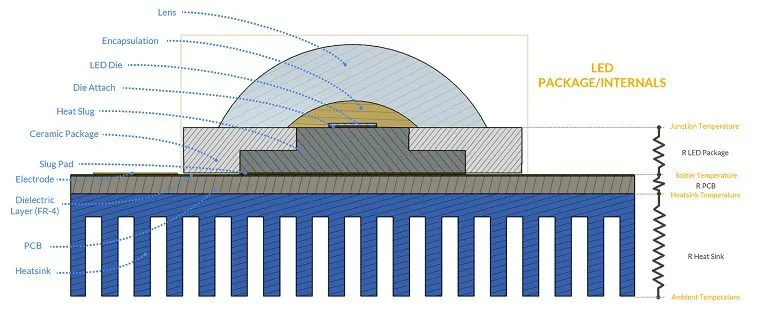

- Excess heat is the main culprit: About 80% of electrical energy converts to heat. If heat is not efficiently dissipated, the chip’s junction temperature rises rapidly.

- Result: High junction temperature accelerates chip aging and phosphor decay, leading to faster brightness loss.

Industry Pain: Promised Lifetime Not Achieved

Many market products show severe light decay within just two years due to poor thermal design or unstable current control. Only a balanced approach across thermal, electrical, optical, and material systems ensures a reliable LED lifetime promise.II. Four Technical Strategies to Minimize Lumen Degradation

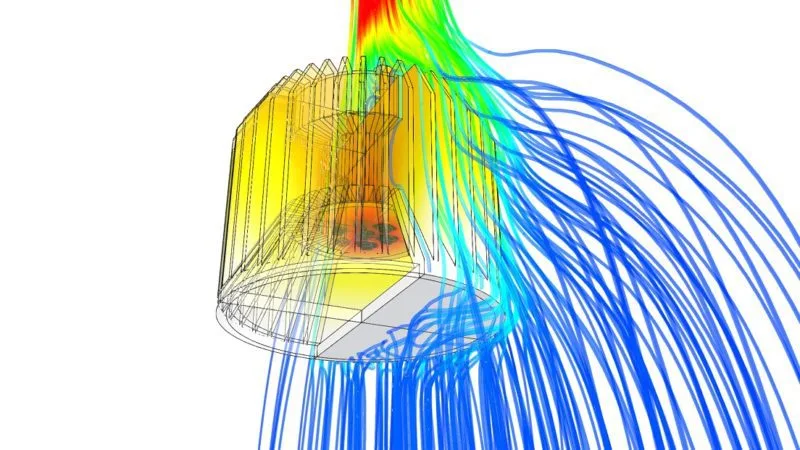

1. Superior Thermal Management

Efficient thermal design is the foundation of LED longevity

| Key Strategy | Technical Details & Advantages | 【Product Example】 |

|---|---|---|

| Precise Junction Temperature Control | Keep LED junction temperature ≤85°C as a scientific basis for lifespan assurance. | 250W T-Shape Bulb adopts high-conductivity aluminum, achieving an extended L70 lifetime. |

| Passive Cooling Design | Utilizes high-conductivity aluminum for passive heat dissipation and maintenance-free operation. | Industrial-grade T-series design acts as an integrated heat sink system. |

2. Stable Driver & Current Control

constant current circuit

| Key Strategy | Technical Details & Advantages | 【Product Example】 |

|---|---|---|

| De-rated Operation Design | Reserves current margin to reduce heat and ensure longer operational life. | LED chips run at optimal temperature for consistent performance. |

| High-Precision Constant Current Driver | Current fluctuation ≤5%, preventing surge damage and ensuring light stability. | All product lines feature branded constant-current drivers with excellent voltage tolerance. |

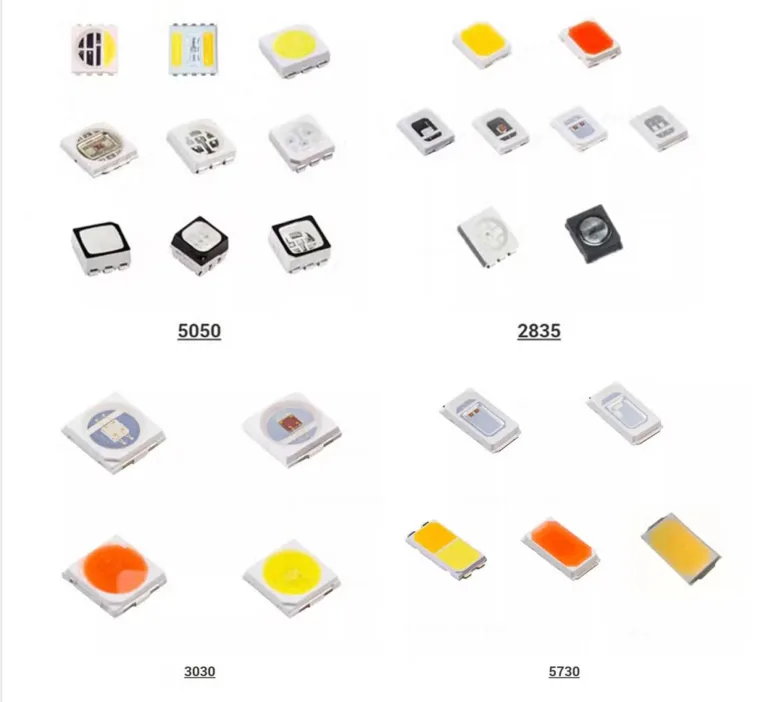

3. Advanced Material System

High-quality materials maintain color stability and optical consistency

| Key Strategy | Technical Details & Advantages | 【Product Example】 |

|---|---|---|

| Premium Encapsulation and Phosphor | Low-decay silicone and high-temperature phosphor prevent yellowing and lumen drop. | Ensures consistent color temperature even after years of operation. |

| Anti-Corrosion Coating Process | Special anti-sulfidation coating on electrode junctions prevents chemical damage. | Purification lamps designed for harsh or chemical-rich environments. |

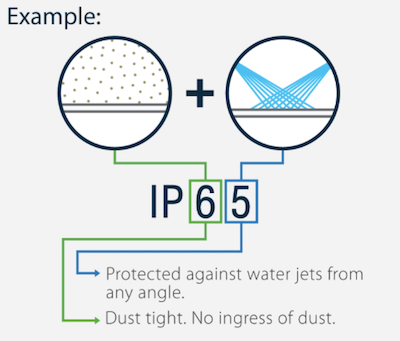

4. Environmental Protection & Sealing

High-seal structure ensures long-term performance in demanding conditions

| Key Strategy | Technical Details & Advantages | 【Product Example】 |

|---|---|---|

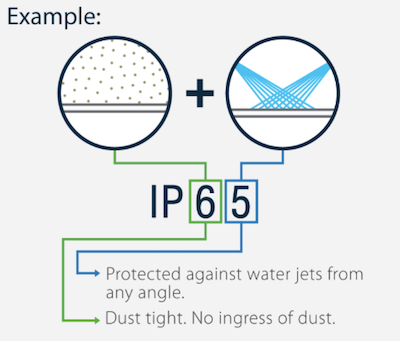

| High Protection Rating Design | IP65~IP66 waterproof and dustproof protection for extended durability. | Tri-proof / Ceiling Lamps designed for humid and dusty environments. |

III. Contact Us — Reliable Technology for Your LED Projects

We specialize in the integrated optimization of thermal, electrical, and material systems to deliver high-stability, long-lifetime LED lighting for global partners.

For detailed product catalogs, L70 lifetime test reports, or OEM/ODM cooperation, please feel free to reach out.

【Contact Us Now for Full Technical Specs & Quotation Support】

[SHAOXING CHANTY LIGHTING CO., LTD] | 🌐 [okaybright.com] | 📧 [kevin@yleds.com] | ☎ [+86 151 6756 6359]